Antimony Ore Mineral Processing

The gravity method process of antimony ore is suitable for most antimony ore process plants because antimony ore are minerals with high density and coarse grain size, which are easy to separate from gangue by gravity method method.

Flotation is the most important extraction method for antimony minerals. Barium sulfide minerals are easy-floating minerals, and most of them use flotation methods to increase the ore crystal position. Among them: stibnite often uses lead salt as activator, and also uses copper salt or lead salt and copper salt, and then floats with collector. Commonly used collectors are butyl xanthate or a mixture of shale oil and ethyl sulphide, the foaming agent is pine oil or No. 2 oil; cerium oxide ore is a difficult ore.

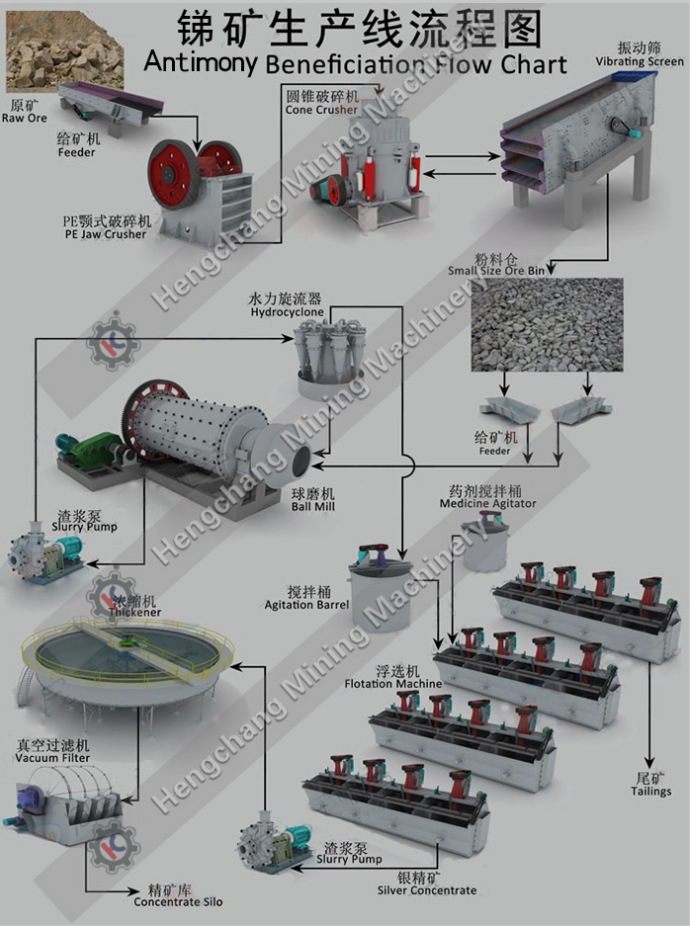

Flotation processing of indruction:

The ore after hand sorting will go through coarse crushing and fine crushing, during which the size of mineral should be under 30mm, and screening classification have three size fractions, 8-30mm, 2-8mm, 0-2mm. then the three kind of minerals will go respectively Jt4-2 Sawtooth Wave Jig to gravity separation. The mixted concentrate from the last stage will be go into the gravity concentrate district. Then after the process of gravity, there will be a process of flotation, the tailings from the preview gravity separation will be grinded, separated, stirred, and separated. And the flotation will apply the process of one roughing, three cleanings, and two scavenging. Then high grade antimony fine powder will be produced. The tailings from the flotation will be reelected by shaking table to recycle the fine antimony particles, which we can get high grade antimony concentrate and tailings.