Stone crusher

Product details

Spring cone crusher can be used to crush hard and medium hard minerals, rocks, iron ores, limestone, copper ores, quartz, granite, sands tones, etc... In a whole production line, the cone crusher is usually used for secondary or tertiary crushing process, or first crushing.

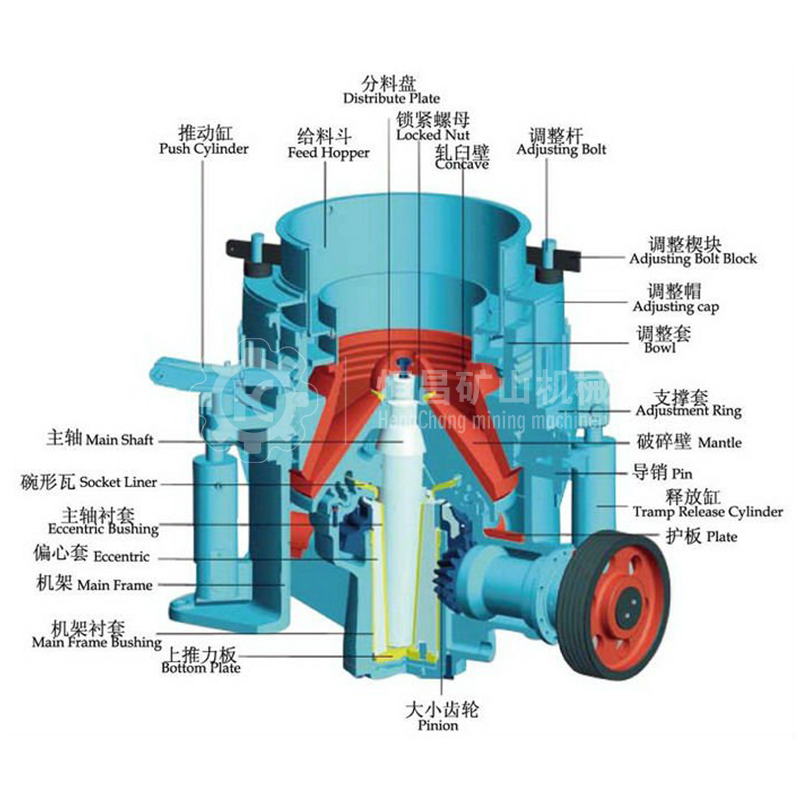

When a spring cone crusher works, its motor drives the eccentric bushing via spring coupling, transmission shaft and a couple of cone gear wheels. The crushing cone axis is forced to swing by the eccentric bearing bushing, which drives the mantle periodically moving close and far to the bowl liner. During the moving process, the raw materials are pressed, impacted and finally crushed in the crushing chamber.

Spring cone crusher has an overloading protection system, to avoid overload material damage cone crusher liner. If the machine is overloaded, the spring insurance system will take effect, quickly to discharge the few materials in the crushing cavity, the discharge port size enlarged at the same time.

Model | Feeding Size (mm) | Range of Output Size(mm) | Capacity (t/h) | Motor Power (kw) | Weight (t) | Overall Dimension (mm) | |

PYB | 600 | ≤ 75 | 12-25 | 15-25 | 30 | 5 | 2234×1370×1675 |

PYD | ≤ 35 | 3-13 | 5-23 | 5.3 | |||

PYB | 900 | ≤ 115 | 15-50 | 50-90 | 55 | 11.2 | 2692×1640×2350 |

PYZ | ≤ 60 | 5-20 | 20-65 | 11.2 | |||

PYD | ≤ 50 | 3-13 | 15-50 | 11.3 | |||

PYB | 1200 | ≤ 145 | 20-50 | 110-168 | 110 | 24.7 | 2790×1878×2844 |

PYZ | ≤ 100 | 8-25 | 42-135 | 25 | |||

PYD | ≤ 50 | 3-15 | 18-105 | 25.3 | |||

PYB | 1750 | ≤ 215 | 25-50 | 280-480 | 160 | 50.3 | 3910×2849×3809 |

PYZ | ≤ 185 | 10-30 | 115-320 | 50.3 | |||

PYD | ≤ 85 | 5-13 | 75-230 | 50.2 | |||

PYB | 2200 | ≤ 300 | 30-60 | 490-750 | 260-280 | 80 | 4622×3302×4470 |

PYZ | ≤ 230 | 10-30 | 200-580 | 80 | |||

PYD | ≤ 100 | 5-15 | 120-340 | 81.4 | |||