Stone crusher

Product details

Introduction: Hammer crusher is used as fine crusher for mining, metallurgy, construction and some other industries. It is used for crushing medium hard materials with weak abrasiveness, and the compression strength of the materials to be crushed should not exceed 100MPa, and the water content should be lower than 15%.

Processing Materials: Rock gold ore, rock coltan ore, rock tin ore, rock tungsten ore, rock iron ore, rock manganese ore, rock chrome ore, stones, gravel, coal, granite, marble, limestone, glass and some other materials.

Application Range: Hammer crusher is widely used for crushing various materials like stone, rock gold, rock coltan, rock tine ore, granite, trap rock, coke, coal, manganese ore, iron ore, emery, fused aluminum, oxide, fused calcium carbide, lime stone, quartzite, alloys, glass, etc.

Advantages and Characteristics:

1. Easy installation and maintenance.

2. Developed structure and long service life.

3. Difficult deformation with high strength.

4. Unblocked material flow and large production capacity.

5. Smooth and reliable performance.

6. Low consumption of spare parts and low maintenance costs.

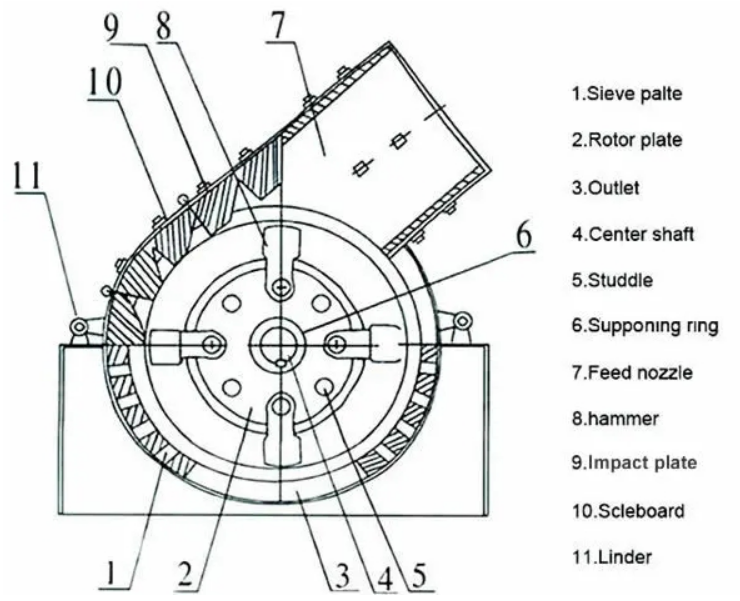

Working Principle:

The motor drives the rotor to rotate at a high speed through the belt, and on the rotor there are series of hammers. When the material get into the working area of hammers, the rotating hammers with high rotation speed are crushing the material, the crushed product meeting the required size can be discharged by the outlet and become the final products, the large size product are brought back to the crushing area by the hammers for being re-crushed until they reached the required size.

Technical Parameter

Model | Feeding Size | Discharging Size | Capacity | Power | Weight | Dimensions |

PC400×300 | ≤200 | ≤25 | 5-10 | 5.5 | 800 | 900×670×860 |

PC500×350 | ≤200 | ≤25 | 8-15 | 11 | 1200 | 1000x770x900 |

PC600×400 | ≤210 | ≤30 | 10-22 | 18.5 | 2200 | 1200×1050×1200 |

PC600×600 | ≤250 | ≤30 | 15-30 | 45 | 2140 | 1300X1000X1250 |

PC800×600 | ≤250 | ≤35 | 18-40 | 55 | 2450 | 1310×1180×1310 |

PC800×800 | ≤250 | ≤35 | 25-45 | 55 | 3050 | 1440×1740×1410 |

PC1000×800 | ≤300 | ≤40 | 25-50 | 75 | 5900 | 1600×1390×1575 |

PC1000×1000 | ≤300 | ≤40 | 30-55 | 132 | 8000 | 1800×1590×1775 |

PC1200×1200 | ≤350 | ≤40 | 35-65 | 180 | 14000 | 2060×1600×1890 |

PC1400×1400 | ≤350 | ≤40 | 50-100 | 280 | 32000 | 2365×1870×2220 |

PC1600×1600 | ≤350 | ≤40 | 100-150 | 480 | 37500 | 3050×2850×2800 |