Mineral Classification Equipme

Product details

The Spiral Classifiers are divided into single spiral classifiers and double spiral classifiers. Beside, they are also divided into high weir spiral classifiers and sinking spiral classifiers. If the overflow edge is higher than the center line of spiral shaft and lower than the external diameter of spiral at the overflow end, the spiral classifiers are high weir ones. If the overflow edge is higher than the center line of spiral shaft and also higher than the external diameter of spiral at the overflow end, the spiral classifiers are sinking ones. High weir classifiers are usually used for the classification with particle size of below 0.2mm. Sinking type classifiers are usually used for the classification with particle size of below 0.05mm.

The Single Spiral Classifier is widely used to pre-grading and inspection grading in closed circuits when used in the production flow of metal processing. According to the difference in sedimentation rate of mineral particles and mud, the particle sizes of ores with 1.5mm-0.03mm are classified. Waste mud or water for ore sand can be separated from the ores. It's also usually applied to ore washing, desliming and dehydration and so on.

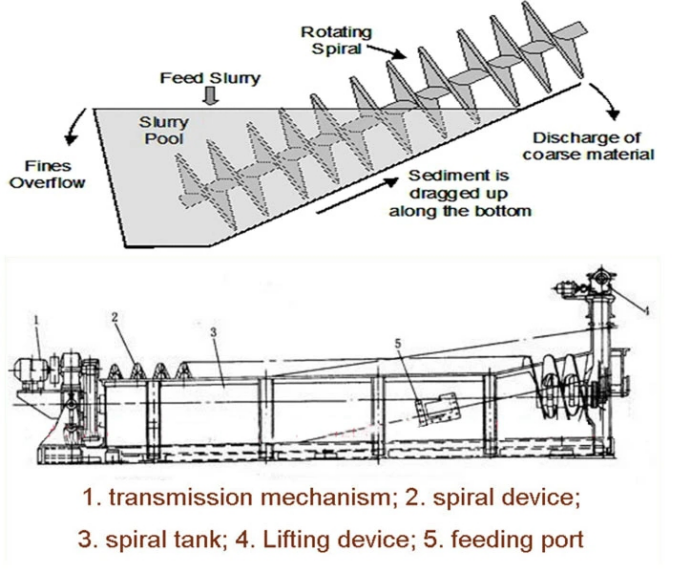

working principle:

The Classifier is composed of transmission mechanism, (left, right) spiral water tank, lifting device, lower support, lubricating device, ore discharge valve, feed inlet, etc. Different grains have different specific gravity and sedimentation rates in slurry;Spiral classifier allows fine ore to flow in the water,while coarse ore sinking to the bottom.Its spiral axle can filter materials and coarse materials to the feeding mouth and discharge fine materials from the pipe.

The water tank of this Spiral Classifier machine is installed obliquely. The angle of inclination is determined according to equipment configuration of equipment in the process flow. The (left, right) spirals driven by the transmission mechanism rotates in the water tank. The finely grained slurry enters the water bank from the feed inlet at one side and forms one slurry precipitation zone, whose surface area and volume depends on the value of the water tank's inclination angle and the height of overflow edge. The spirals rotating at a low speed play a certain stirring role. After the slurry is stirred, the light and fine particles float above the surface and overflow from the overflow edge. Then they flow into the next working procedure of ore dressing. The heavy and thick particles sink into the bottom of the water tank and become return sand which is transported by the spirals to the ore discharge mouth for discharge.

If ore grinding and classification are closed loop operation, the return sand discharged from the ore discharge mouth still goes into the mill for further grinding. The gold refining machine Spiral Classifier normally forms closed-circuit operation together with ball mill.

Model | spiral diameters | Spiral Speed | Output | Motor Power | Weight | ||

Circulating Load | Overflow Quantity | Lift Lower | Drive | ||||

mm | r/min | t/24h | t/24h | kw | kw | t | |

FG-3 | Φ300 | 8.3-2.2 | 30-80 | 15 | 2.2 | 1.1 | 0.67 |

FG-5 | Φ500 | 8.5-15.5 | 143-261 | 32 | 2.2 | 1.1 | 1.6 |

FG-7 | Φ750 | 4.5-9.9 | 256-564 | 65 | 2.2 | 3 | 2.83 |

FG-10 | Φ1000 | 3.5-7.6 | 473-1026 | 85 | 2.2 | 5.5 | 4 |

FG-12 | Φ1200 | 5、6、7 | 1170-1600 | 155 | 2.5 | 5.5 | 8.54 |

FG-15 | Φ1500 | 2.5、4、6 | 1140-2740 | 235 | 2.2 | 7.5 | 11.68 |

FG-20 | Φ2000 | 3.6、5.5 | 3890-5940 | 400 | 3 | 15 | 20.45 |

FG-24 | Φ2400 | 3.64 | 6800 | 580 | 3 | 15 | 25.65 |

FG-30 | Φ3000 | 3.2 | 11650 | 893 | 4 | 22 | 40.9 |