Mineral Classification Equipme

Product details

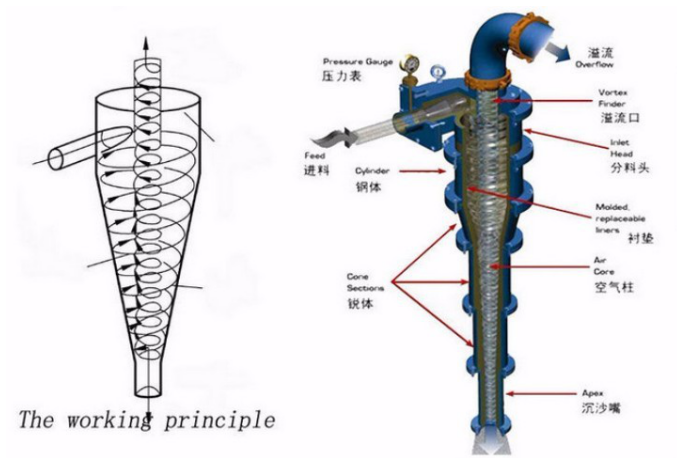

The theory of hydro cyclone action is that particles within the flow pattern are subjected to two opposing forces- an outward centrifugal force and an inwardly acting drag. The centrifugal force developed accelerates the settling rate of the particles thereby separating particles according to size, shape, and specific gravity. Faster settling particles move to the wall of the cyclone, where the velocity is lowest, and migrate to the apex opening. Due to the action of the drag force, the slower-settling particles move towards the zone of low pressure along the axis and are carried upward through the vortex-finder to the overflow.

working principle

after pumped into the cylinder by sand pump (or height difference) at certain pressure (generally 0.5-2.5kg/cm) and flow velocity (around 5-12m/s) through the ore feed pipe and along the tangential direction, the pulp will rotate along the cylinder wall quite fast to generate substantial centrifugal force. Under the action of centrifugal force and gravity, thick and heavy ore grains are thrown to the wall, moved down along track of the spiral line and discharged out of the sand discharge nozzle at the cone bottom. While fine ore grains form ascending pulp flow with water at the cone center that is later discharged out of the overflow pipe.

1.Simple structure; light and nimble; no moving part

2.Low maintenance charge; easy to attach and detach; save floor space; low construction expense

3.Large processing capacity

4.The classification particle size can reach 10μm.

Specification | Capacity (m 3 /h) | Separation Particle Size (μm) | Diameter of Overflow Outlet (mm) | Diameter of Spigot (mm) | Inlet Pressure (MPa) |

FX-150 | 10-23 | 25-74 | 30-50 | 8-22 | 0.060-0.15 |

FX-200 | 17-38 | 28-80 | 40-65 | 16-32 | 0.060-0.15 |

FX-250 | 24-53 | 30-82 | 65-100 | 16-40 | 0.060-0.15 |

FX-300 | 40-100 | 36-90 | 65-120 | 20-40 | 0.060-0.15 |

FX-350 | 56-118 | 40-100 | 80-120 | 30-70 | 0.060-0.15 |

FX-375 | 74-157 | 42-105 | 90-135 | 30-70 | 0.060-0.15 |

FX-450 | 90-192 | 44-110 | 100-150 | 30-70 | 0.060-0.15 |

FX-500 | 128-300 | 50-115 | 130-220 | 35-100 | 0.060-0.15 |

FX-610 | 200-468 | 57-125 | 160-260 | 65-110 | 0.060-0.15 |

FX-660 | 237-524 | 60-130 | 180-280 | 80-150 | 0.060-0.15 |