Gravity Separator

Product details

Introduction: Jig separators are devices used mainly in the mining industry for mineral processing, to separate particles within the ore body, based on their specific gravity.

Processing Materials: Gold, tin, columbium, tantalum, titanium, barium, tungsten, barite, chrome, manganese, zircon, lead, zinc, copper, aluminum, coal and some other materials.

Application Range: It is widely used to separator tungsten, tin, gold, red iron, brown iron, manganese, titanium, antimony, lead, tantalum, niobium and other minerals.

There are many applications where the jig separator of particular value and cannot be equaled for economical and efficient performance. They are effective in processing precious and base metal, rare metal and non-metallic minerals.

Advantages and Characteristics:

1. High processing capacity, concentration ratio and high recovery

2. Fabricated with highest quality material

3. Easy to install, operate and maintain

4. The pulsation curve is saw-tooth wave shape facilitate heavy mineral to settling

5. The pulsation speed very easy adjusted by regulator

6. Suitable for roughing and desliming

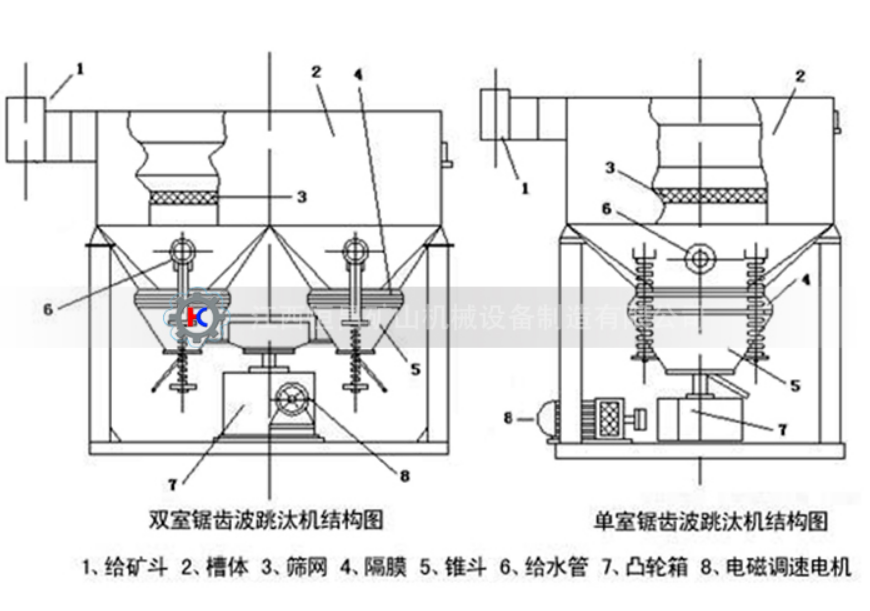

Working Principle:

Jig separator need water to work, and it loosens materials in vertical alternative water-flows, and it forms different layers of materials of different densities and discharges both layers from up and down discharging ports separately. The basic composition of jigger is jigging chambers, also called jigging boxes, and there are screens in each chamber.

Water and raw ore will be fed from one end of the jigger screen, the ore granules will move in the vertical alternative water-flows. Layers will be formed because of density difference of materials. The minerals with small density will be in the up layer and will flow together with the up pulp flow while material with bigger density will be in the down layer and will discharged from the down discharging port as jigging concentrate.

Technical Parameter

Model | Jigging Area | Feeding Size | Water Added | Water Pressure | Capacity | Power | Dimension (mm) | Weight |

JT0.57-1 | 0.57 | <6 | 1-2 | ≥0.05 | 1-3 | 1.5 | 1550x780x1530 | 610 |

JT1-1 | 1.04 | <10 | 2-3 | ≥0.05 | 2-4 | 2.2 | 2270x1110x1890 | 900 |

JT2-2 | 2.28 | <10 | 2-4 | ≥0.05 | 4-8 | 3 | 3225x1550x2050 | 1640 |

JT3-1 | 3.3 | <10 | 3-6 | ≥0.05 | 6-10 | 5.5 | 2745x2000x3030 | 3260 |

JT4-2 | 4.33 | <25 | 4-8 | ≥0.05 | 10-15 | 7.5 | 4240x1990x2750 | 4200 |

JT4-2A | 4.33 | <25 | 4-8 | ≥0.05 | 10-15 | 4x2 | 4240x1990x2750 | 4200 |

JT5-2 | 4.86 | <10 | 3-6 | ≥0.05 | 12-20 | 7.5 | 3600x2000x2600 | 4500 |