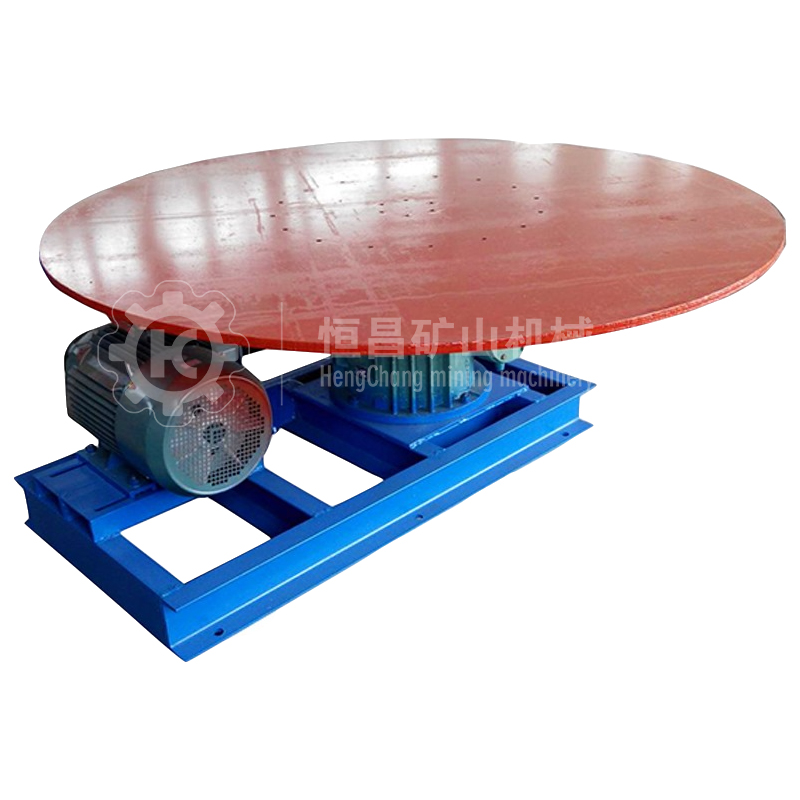

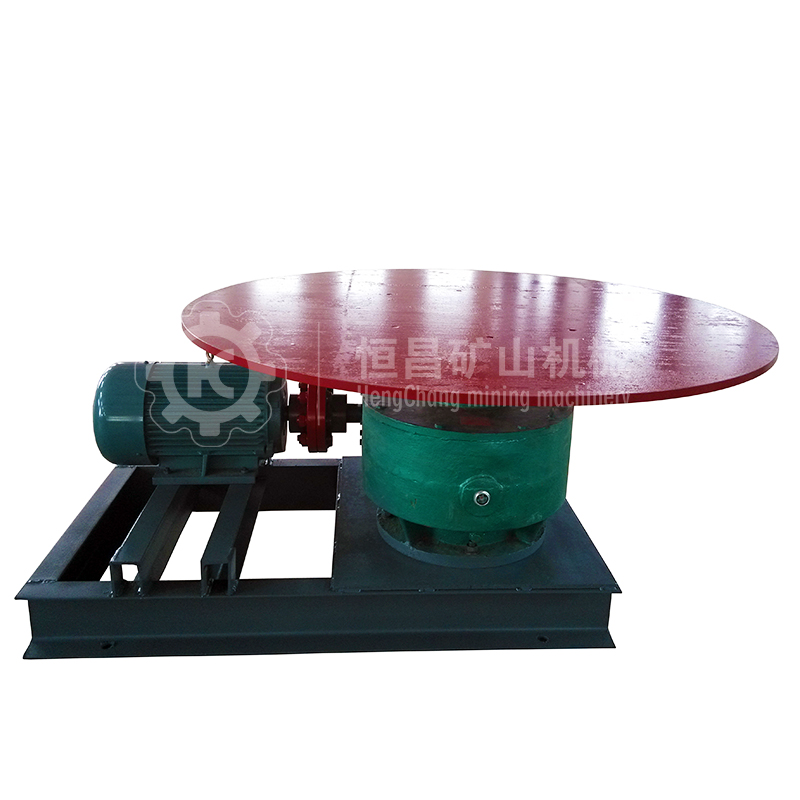

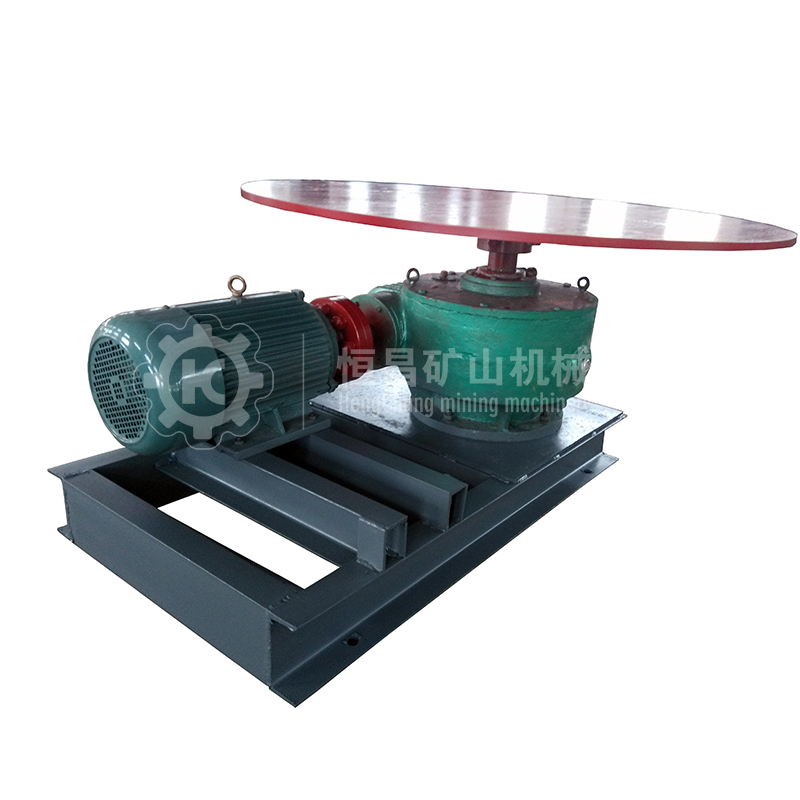

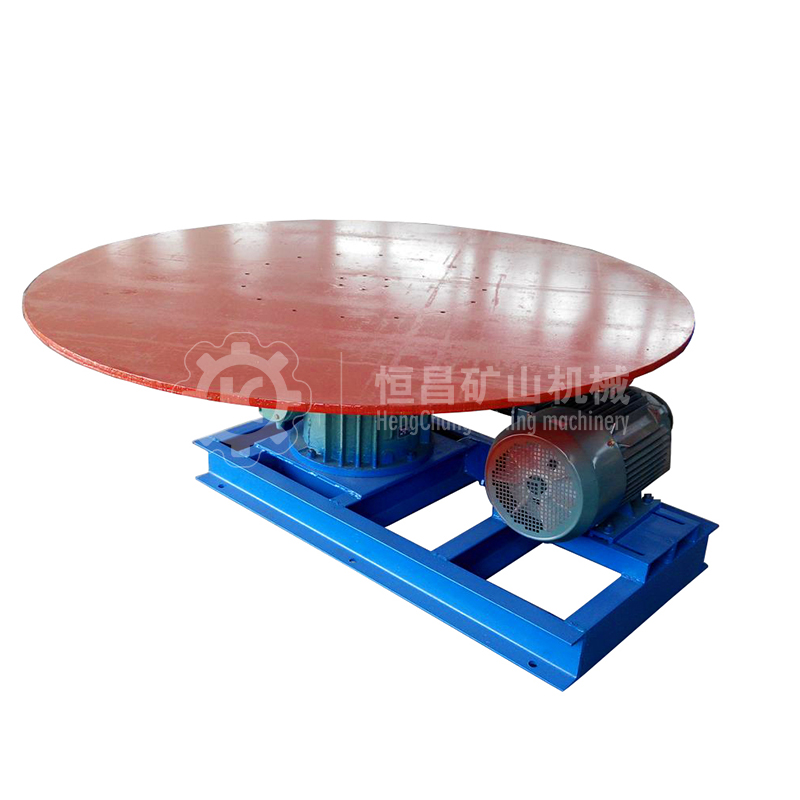

Feeder Machine

Product details

Introduction:

DK Disk feeder is of suspension opening type, suitable for feeding the power material with grain size less than 20mm. It is hung above bottom opening of fine-ore bin. The quantity for ore feeding is adjusted through adjusting the position of scraper.

应用Application Range: Disk Feeder is widely used as a continuous volume of charging equipment, can evenly and continuously material will be fed to the next equipment, the feed quantity can be adjusted, can feed powder, small bulk material (such as coal, clay and so on), is the general mill, dryer used equipment.Among them, DK for hanging open, DB for closed type. Disk feeder is widely used in metallurgy, mining, building materials, coal, electric power and other industries a variety of non viscous material feed.

Advantages and Characteristics:

Disk feeder for hoisting, closed. Mainly for reducing air leakage or dust system, so as to decrease the environment pollution to the minimum degree. Disc feeder main body is rotated about a vertical axis disc. There is a central disc is connected under the hopper mouth height adjustable blanking sleeve material, material from the sleeve and disc gap leakage dispersion, and scraper material from the disc scraping down. Feed amount can be changed by cutting sleeve and disc gap size and the discharge position to adjust. With the observation window, can be readily observed material feeding and running situation of the equipment.

working principle:

Model | Dis diameter(mm) | Capacity (t/h) | Feed size(mm) | Power(kw) | Weight(kg) |

DK6 | 600 | 0.6-3.9 | 25 | 1.1 | 400 |

DK8 | 800 | 1.4-7.6 | 30 | 1.1 | 555 |

DK10 | 1000 | 2.5-16.7 | 40 | 1.5 | 827 |

DK13 | 1300 | 4.2-27.9 | 50 | 3 | 1150 |

DK16 | 1600 | 7-48.6 | 60 | 4 | 2125 |

DK18 | 1800 | 9.2-60 | 70 | 5.5 | 2900 |

DK20 | 2000 | 13.6-38 | 80 | 5.5 | 3140 |